-300x200.webp)

Curtain Wall Design as Engineering Judgment

Curtain Wall Design as Engineering Judgment How SunFrame Integrates Structure, Materials, and Interfaces in Complex Façade Projects In many projects, curtain walls are often seen

Through years of experience in curtain wall projects, SunFrame has always regarded the waterproof performance of curtain walls as one of the core control points in the design and construction process. Combined with the leakage mechanism of the curtain wall system, water infiltration usually have three basic conditions: the presence of gaps, the intrusion of water, and a pressure differential at the joints. In view of these factors, effective prevention and control ideas include: minimizing gaps, shielding the system from direct water exposure, and reducing the wind pressure difference around joints. SunFrame fully implements the following waterproofing solutions from the design source to the construction implementation:

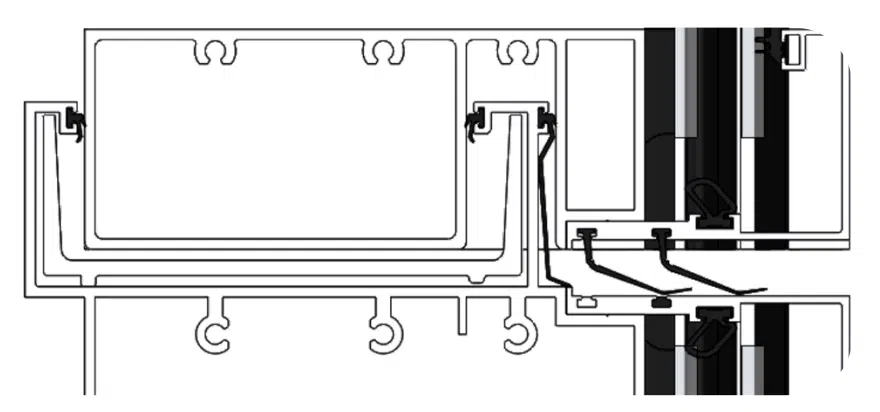

Following the equal-pressure principle, we set up equal-pressure chambers and pressure introduction holes in the aluminum profile structure. The equal-pressure chamber maintains balance with the outdoor pressure through the introduction hole, “transferring” the wind pressure difference to the indoor side. This can prevent rainwater from penetrating into the curtain wall system with the help of the pressure difference. This method is effective on active waterproofing, which has been widely used in high-performance curtain wall projects for many years by SunFrame.

Design outdoor drainage holes on the aluminum profiles to promptly drain rainwater that enters the system through micro-slits. Then remove the accumulated water in the isobaric cavity to ensure that the curtain wall system is dry and reliable. This is one of the effective “water control” methods currently recognized in the industry. Below is the specific example for this design concept.

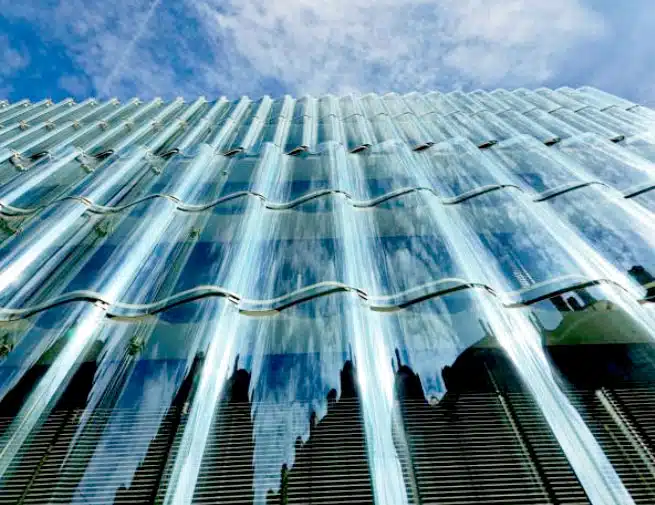

UN150 Glass Curtain Wall

Four-layers waterproofing design

For certain projects, SunFrame offers the option of integrating water collection and drainage pipes. These systems gather potential leakage and discharge it through designated outlets, enhancing the overall redundancy and safety of the curtain wall system.

Select high-quality structural silicone sealants, weatherproof sealants, and perimeter sealants, and strictly inspect the product validity period. The float glass used needs to be edge-processed and controlled at a dimensional accuracy to ensure continuous and reliable sealing performance.

Sealant must be applied in a dry and clean environment. The construction during rainy conditions is strictly avoided. For structural sealant application, the workshop temperature should be kept below 27°C, with relative humidity not lower than 50%. This is to ensure that the performance of the sealant material is fully exerted.

Ensure that there is no dust, oil or impurities on the surface of the aluminum frame, glass or joints. After sealing, it should be filled and compacted, with a smooth and even finish. Besides, post-maintenance should be done to avoid human interference or exposure during this period.

In compliance with industry standards, SunFrame performs staged water penetration tests during the curtain wall installation process to detect problems in advance and repair them in time.

Concealed work inspection focuses on the installation quality of the aluminum profile frame, secure connection of joints, and proper construction of expansion joints, etc. The final acceptance is the overall quality confirmation before the system is delivered.

Focus on checking whether the opening window is well sealed, whether the hardware is durable and reliable, and ensure that the switch is flexible and smooth to use.

Cleaning should be carried out using the building’s own window cleaning system or by certified professional cleaning companies. A detailed cleaning plan must be in place to ensure no damage is caused to the curtain wall system during the process.

After completion, SunFrame will provide complete acceptance information and assist the owner in formulating a regular maintenance and repair plan for the curtain wall according to the usage guidelines. This ensures the long-term and stable operation of the curtain wall system.

SunFrame always adheres to the principle of “rigorous design, meticulous construction, quality first”, and is committed to providing every customer with a safer and more reliable curtain wall system. Through scientific waterproof design and strict control of construction details, we not only solve the problem of water seepage, but also provide long-lasting facade protection for the building. Choosing SunFrame means choosing the professional guarantee of curtain wall waterproofing.

-300x200.webp)

Curtain Wall Design as Engineering Judgment How SunFrame Integrates Structure, Materials, and Interfaces in Complex Façade Projects In many projects, curtain walls are often seen

From Curtain Wall to Facade: SunFrame’s Insights into Facade Engineering Introduction | Why We Focus on Facade, Not Just Curtain Wall The curtain wall has

The Restraint Behind a Perforated Aluminum Façade One day, while passing by a school, I found myself paying attention to its exterior. Along the corridors

Rooftop Multi-Level Void Curtain Wall Construction — Sunframe’s Systematic Solutions for Complex High-Altitude Conditions As supertall buildings reach unprecedented heights and embrace increasingly complex spatial