What Is Exposed frame curtain wall

What are the advantages and disadvantages of an exposed frame curtain wall system?

Advantages of exposed frame curtain walls include design flexibility, as the exposed mullion framing allows for different glass types, finishes, and architectural expressions. They offer good structural performance and impact resistance. Exposed frame systems are also generally more cost-effective than unitized curtain walls for mid-rise buildings. Disadvantages can include higher air infiltration and thermal bridging than unitized systems due to the exposed aluminum mullions. Exposed frame systems require more intensive sealant work in the field during installation. Long-term maintenance of exposed sealants and gaskets is needed to prevent leaks.

How does an exposed frame curtain wall differ from a unitized curtain wall system?

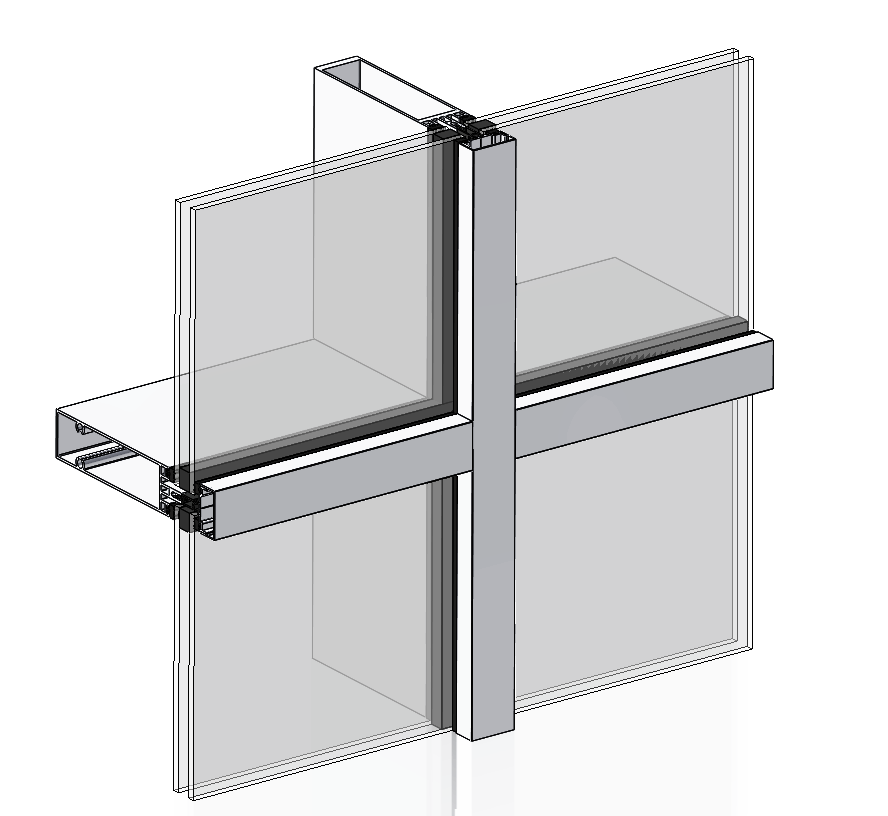

In an exposed frame curtain wall, the aluminum mullions and pressure plates are, as the name suggests, exposed to the exterior. It is typically stick-built, with components assembled piece-by-piece on site.

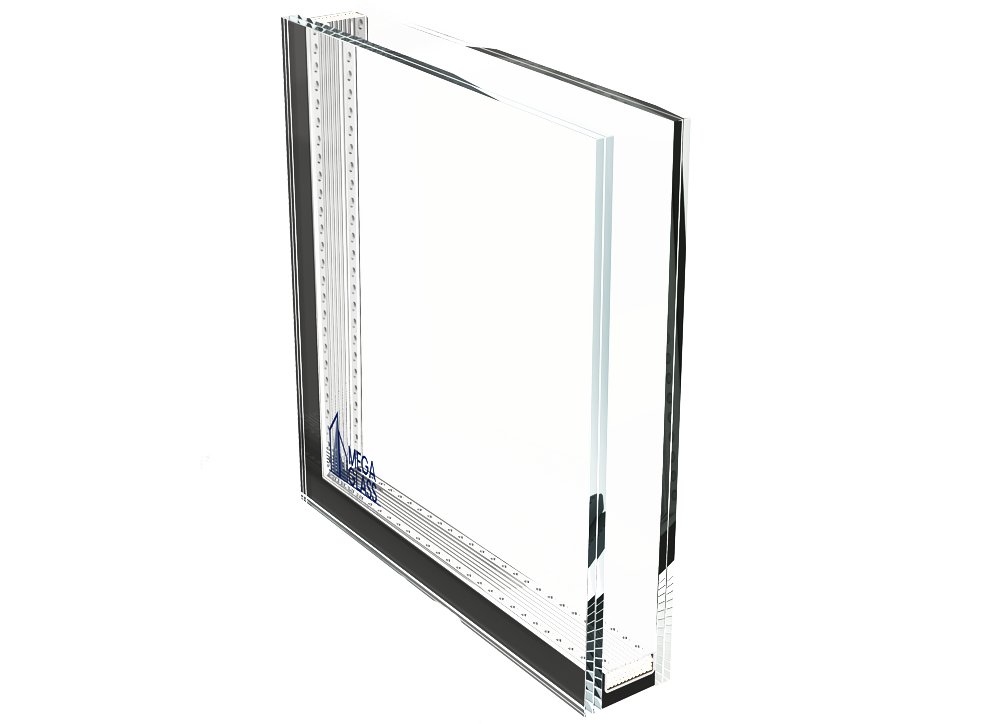

A unitized curtain wall has no exposed frame on the exterior, with the aluminum framing fully captured between glass lites in pre-glazed panels that are efficiently assembled into a structural anchorage system on site.

Exposed frame systems allow more adaptability in component sourcing but require intensive field labor. Unitized systems have superior air/water performance but higher upfront costs.

What are typical components and materials used in exposed frame curtain wall construction?

Various glass makeups are used – insulated low-e, tempered, laminated, ceramic fritted, and others depending on performance needs. Steel reinforcements may be required for wind load resistance in certain applications.

What factors influence the cost of installing an exposed frame curtain wall?

Pricing for exposed frame systems is affected by material costs – aluminum quantities, glass specifications, quality of finishes, etc. The degree of system customization and geometric complexity also impacts cost, due to increased engineering and fabrication scope.

Installation costs are influenced by required labor intensity, which is higher for stick-built systems versus pre-glazed unitized assemblies. Local labor rates, site accessibility, and schedule constraints can further impact pricing.

Overall, exposed frame systems tend to have lower initial costs than unitized systems, making them cost-effective on smaller to mid-size projects. Project-specific variables must be evaluated.

How do exposed frame curtain walls perform in terms of energy efficiency and thermal bridging?

Compared to unitized curtain walls, exposed frame systems are less thermally efficient due to the exposed aluminum framing that bridges the insulating cavity between glass lites. This framing creates discontinuous thermal paths allowing more heat transfer.

Steps can be taken to improve thermal performance, such as using structural thermal break materials within aluminum framing members. Triple glazing, low-e coatings, and warm-edge spacers can boost glass insulation properties.

Overall, however, the exposed aluminum in these systems creates inherent thermal bridging that must be accounted for in energy modeling. Proper detailing and thermally improved framing are critical.

What are best practices for maintaining and repairing exposed frame curtain wall systems?

Regular inspections should check sealant integrity, gasket compression, glass-frame interfaces, and any sealant migration onto exposed finishes. Sealants may require periodic replacement based on joint design, UV exposure, etc.

Any failed wet seals must be addressed immediately to prevent moisture infiltration. Compatible sealants should be used for repairs. Broken glass lites and damaged gaskets/pressure plates need replacement.

Finish degradation on exposed framing may necessitate localized remediation or full-frame reglazing depending on severity. Cleaning protocols with approved materials should be followed.

Diligent maintenance and prompt leak repairs are crucial to prevent insulation wetting, interior damage, and diminished performance over time.