Aluminum façade cladding has become a preferred solution for modern architectural exteriors, thanks to its superior performance and diverse design possibilities. We SunFrame offer a comprehensive range of aluminum façade cladding systems to meet the diverse needs of commercial, residential and public infrastructure projects.

Here are the four main reasons for you to choose us – SunFrame, your trusted partner in aluminum façades.

Our aluminum panels have only one-third the weight of steel with comparable strength.

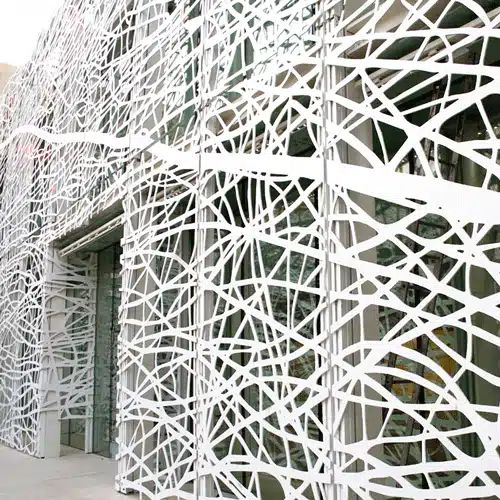

We can produce the aluminum panels in intricate patterns with our CNC cutting technology.

Wind durability and weather resistance are key strengths of our aluminum panels.

Our aluminum panels are compliant with international fire safety standards, ensuring worry-free use.

▶ Styles

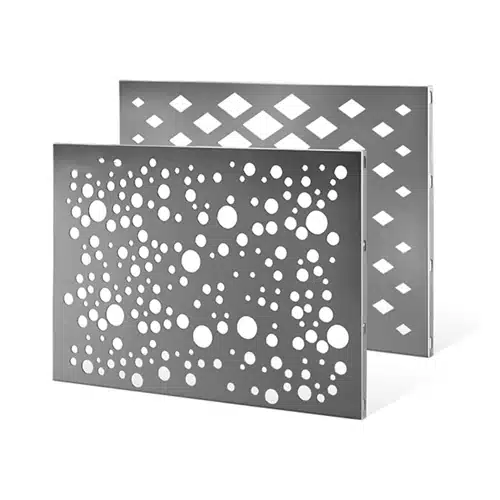

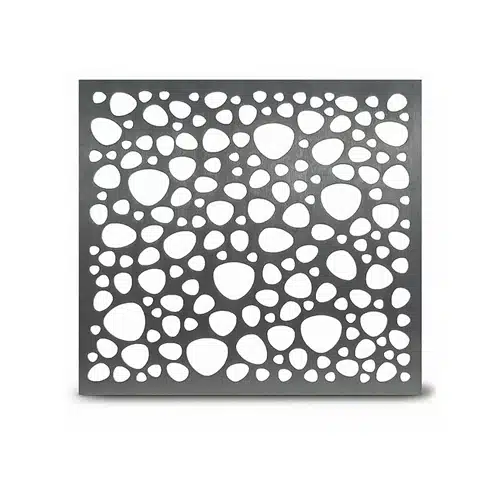

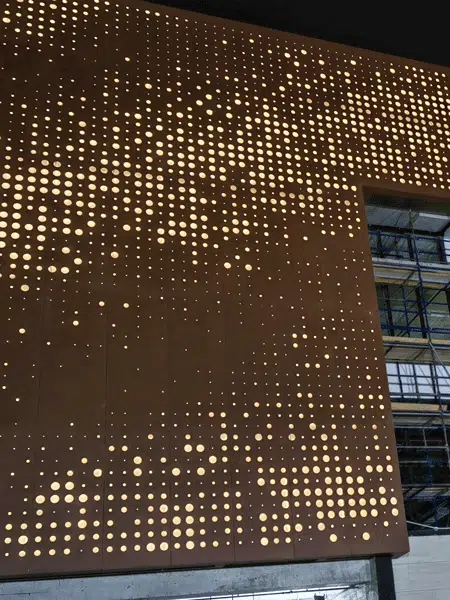

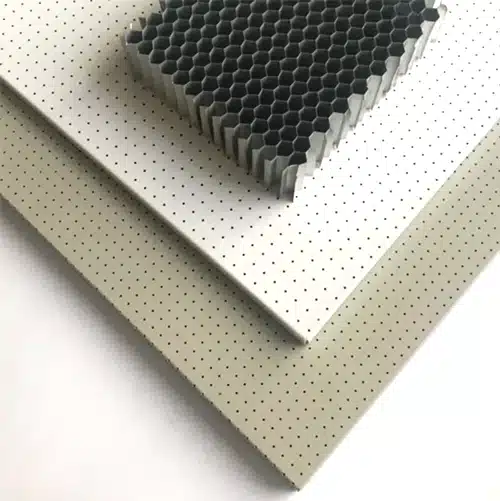

As for styles of perforated aluminum panels, we can make:

① Standard Hole Patterns: round, square, hexagonal, and other conventional designs

② Custom Perforations: tailored designs to meet specific client needs for a unique architectural appearance

③ Image Perforation: transforming photos or logos into perforated designs for creative branding and artistic expression

▶ Crafting Process

When it comes to the crafting process, we have the following two techniques:

They respectively are CNC punching and laser cutting.

With these techniques, we can create precise, regular, or irregular hole patterns which can be used to build high-quality perforated aluminum facades.

We categorize the advantages from the perspectives of functionality and performance as follows:

✔ Excellent Ventilation & Daylight Performance

The perforated design facilitates light penetration and air circulation. And that can create a comfortable indoor environment while ensuring privacy. Therefore, it can satisfy the sunshade requirements in high-temperature regions like the Middle East.

✔ High Aesthetic Effect

Our perforated aluminum panels can be made into diverse patterns including geometric designs and custom graphics (e.g., logos, artwork). And that means they can combine the architectural functionality with artistic effect to enhance façade visual impact. Besides, lighting and colors also can be integrated to create dynamic, layered façade effects.

✔ Lightweight Yet High-Strength

Aluminum is a lightweight material, which can ensure easy transportation and installation while minimizing structural load on buildings.

✔ Highly Customizable

Our CNC or laser cutting technology can realize the creative project by creating the bespoke shapes and perforation patterns.

✔ Weather-Resistant & Low-Maintenance

Surface treatments (fluorocarbon coating, powder coating, etc.) provide superior corrosion/UV resistance, suitable for diverse climatic conditions.

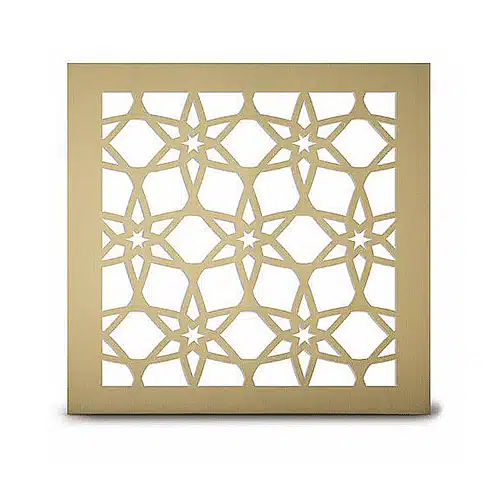

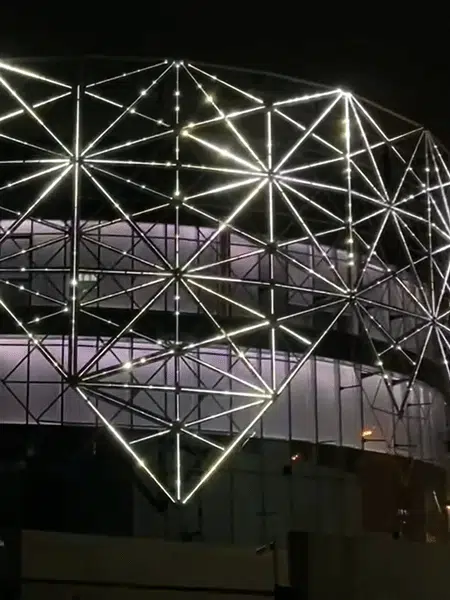

Project Name: G+1 CENTRO MALL

Location: Doha, Qatar

Facade Area: 5,500+ sqm

Products: B1 & B2 Perforated Aluminum Panel Façade

Scope of Work: Full-cycle service (from design to installation)

SunFrame provided a full-cycle façade solution for Doha’s G+1 Centro Mall, delivering over 5,500 sqm of custom perforated aluminum panels inspired by the “Desert Oasis” concept. From design collaboration to on-site installation, our team translated cultural aesthetics into a striking architectural expression, enhancing the mall’s identity with dynamic lighting and intricate perforation patterns.

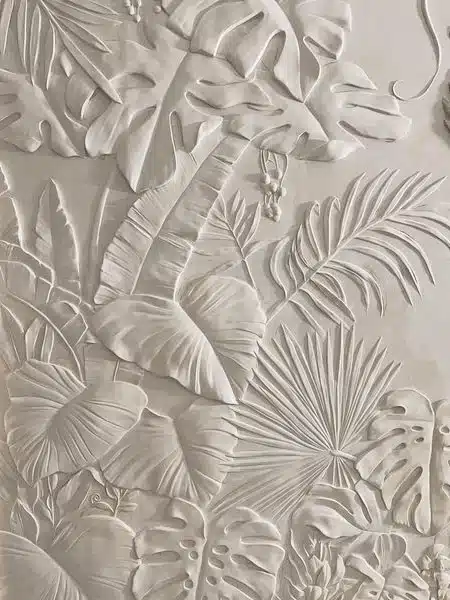

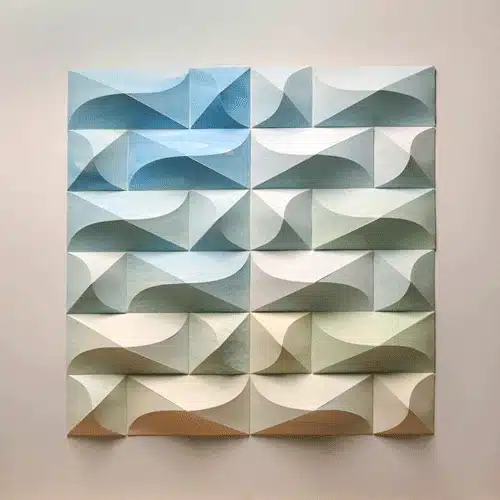

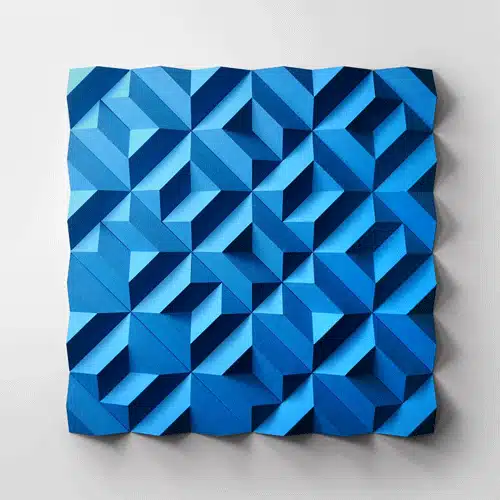

These decorative aluminum panels are primarily used to enhance building aesthetics by blending artistic flair with functional protection.

They can be paired with lighting, perforation, and special coatings to make the building façade a true visual focal point.

The key features of our decorative aluminum panels can be summarized in the four elements below.

✔ Greater Design Freedom with Emphasis on Aesthetics

☞ Unlike perforated panels that focus on light/shadow control, decorative panels prioritize:

Holistic architectural style and façade expression

Complex effects like bas-relief textures, 3D layering, and engraved patterns

Creating strong visual symbols and brand identity

✔ Focal Point Creation with High Visual Impact

☞ In large-scale façade applications:

Serves as key visual anchors or primary focal elements

Enhances recognition through lighting interplay and material contrast

Delivers striking visibility day and night

✔ Compatible with Diverse Craft Techniques

☞ Supports multi-process integration:

Surface engraving | Custom coatings | Metallic textures | Laser etching | Layered assembly | Embossed motifs

☞ Perfect for cultural landmarks, art museums, luxury hotels, and flagship buildings requiring strong visual identity

✔ Ideal for Solid Structures with Cohesive Design Language

☞ Compared to the translucency of perforated panels, decorative panels excel in:

Closed systems or façades requiring seamless integration

Crafting premium, sophisticated, and monumental architectural atmospheres

Project Name: Headquarters of Almana Group

Location: Doha, Qatar

Facade Area: 3,500sqm Decorative Aluminum Panels

Year: 2019-2021

Scope of Work: Facade (from design to installation)

SunFrame engineered the aluminum curtain wall system for Burj Al Mana Tower, delivering precision-cast components and innovative shading solutions that blend traditional Qatari design with modern performance.

▶ Styles

The styles of solid aluminum panels can be divided into these two types:

① Flat Panels: with edge treatments like folding and seamless welding for a sleek, modern look

② 3D-Shaped Panels: ideal for dynamic, sculptural facades

▶ Crafting Process

The crafting process of solid aluminum panels include:

Our solid aluminum panels are famous for the following 4 strengths:

✔ Superior Strength and Durability

Our solid aluminum panels are produced from quality one-piece aluminum sheets and present an excellent structural strength and long-term durability. This is benefit from our factory’s advanced manufacturing expertise and rigorous quality control standards.

✔ Great Performance

They can withstand the harsh weather conditions and resist impact, corrosion, and UV exposure and still keep themselves in a great condition. What’s more, they meet high fire safety standards. They’re also fully recyclable, which are suitable for eco-conscious projects.

✔ High Customization Flexibility

Our solid aluminum panels can be made into different shapes or patterns, or finished in a variety of surface textures according to your specific requirement.

✔ Easy Maintenance and Long Lifespan

The surface coatings on solid aluminum panels are highly resistant to fading, staining, and pollution, which can reduce the maintenance costs and keeps the building facade looking new over time.

Project Name: Guyana CJIA Airport

Location: Doha, Qatar

Curtain Wall Area: 6448 sqm

Supplied Products: Solid Aluminum Panel and Exposed Frame Curtain Wall

Scope of Work: Site measurement, material supply, installation

SunFrame provided a complete façade solution for the Guyana CJIA Airport project, supplying solid aluminum panels and an exposed frame curtain wall system covering an area of 6,448 sqm. From precise site measurements to material supply and on-site installation, our team ensured seamless integration of performance and aesthetics for this key infrastructure project.

▶ Structure:

The ACP are composed of Aluminum alloy face sheets + Polyethylene or Mineral Core.

If you choose our ACP panels for your facade, you will enjoy the following benefits:

✔ Excellent Flatness with Lower Transportation Costs

ACP panels are lightweight with an extremely flat surface, which ensures a clean, uniform facade. Also, their low weight and flat surface can reduce shipping volume and costs.

✔ Easy Installation and Shorter Construction Time

ACP panels are easy to cut, fold, and install, without the need for complex tools or processes. And that means they are ideal for fast-paced projects where needs to save time and labor.

✔ Flexible Material Adjustments for Diverse Function Requirements

According to the building’s functional requirements, ACP panels can be customized by adding different materials for the functions like enhanced thermal insulation, soundproofing, or fire-resistant cores.

Location: Ghandi Avenue, Nairobi, Kenya

Year: 2019

Facade Area: 9,600 m²

Products: Structurally glazed glass facade, windows, ACP cladding

Scope of Work: Site measurement, material supply, installation

For Nairobi West Hospital, SunFrame supplied and installed aluminum composite panel (ACP) cladding as part of a complete facade package. Our work ensured a durable, energy-efficient skin that complements the building’s contemporary design.

It’s necessary to enhance the aesthetic appeal and durability of your aluminum façade system with a variety of surface treatments.

See which finish types we can provide for your facade.

Finish Type | Features | Durability |

PVDF Coating | Outstanding weather resistance and color retention | 20–30 years |

Anodizing | Strong metallic texture, scratch-resistant | 15–25 years |

Powder Coating | Eco-friendly, cost-effective, and solvent-free | 10–15 years |

Biomimetic Finish | Simulated stone, wood grain, or rust effects | Varies by coating |

Our aluminum panel systems are widely used in various sectors, including:

Commercial complexes

High-rise office buildings

Healthcare and educational facilities

Transportation hubs

Cultural and civic venues

(1) 20+ Years of Industry Experience – We SunFrame have successfully completed over 200 facade projects.

(2) Strong Production Capacity

– 200,000 sqm modern factory for large-scale production

– 200+ engineers and over 1,000 skilled workers

– Annual curtain wall output: 500,000 sqm

(3) Comprehensive Service – From design to installation

(4) Certified Quality Control – Certified with National GB5237, ISO9001, JISH4100, AAMA 2603, UK BS6496, AS2047 & 4284 and more

(5) Professional Project Teams – Dedicated support for every stage of the project